| ID |

Product Name |

Images |

Unit |

Description |

Action |

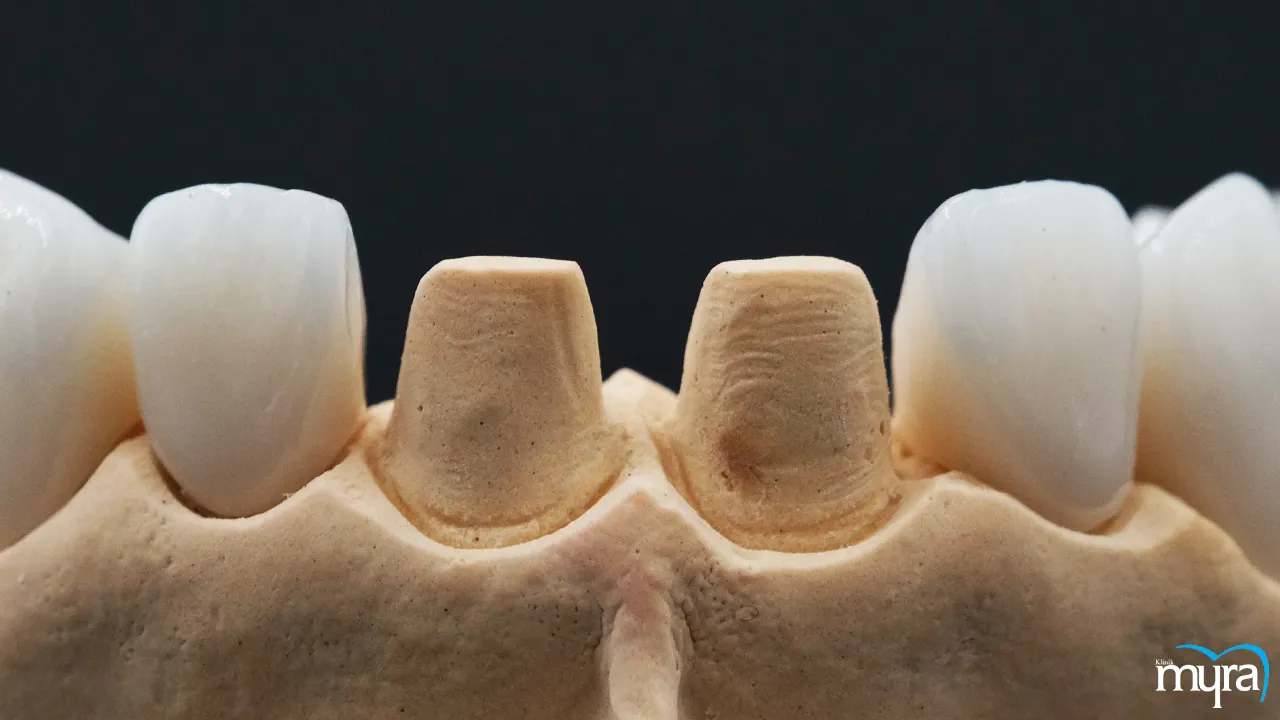

| 3 | Besic Zir |    | 1 - 3 units could be made | What is Besic Zirconia? Besic Zirconia, often referred to as Zirconium Dioxide (ZrO₂), is a ceramic material widely used in dentistry, particularly in dental crowns, bridges, and implant abutments. It’s known for its exceptional strength, durability, and aesthetic appeal. When a product specifies 1-3 units, it typically refers to individual dental crowns or a 3-unit dental bridge.

✅ Advantages of Besic Zirconia:

-

High Strength & Durability:

-

Biocompatibility:

-

Minimal Tooth Preparation:

-

No Metal Base:

-

Corrosion & Temperature Resistant:

-

Precision Fit:

❌ Disadvantages of Besic Zirconia:

-

Opaque Appearance:

-

Chipping Risk (When Layered):

-

High Cost:

-

More expensive than metal-ceramic crowns.

-

Cost may vary depending on the clinic, lab, and material quality.

-

Difficult to Adjust or Remove:

-

Wear on Opposing Teeth:

Why Choose Besic Zirconia?Choose Besic Zirconia if:

-

You need 1-3 units of strong dental restorations (crowns/bridges).

-

You want metal-free, biocompatible materials.

-

You are focused on durability over high-end aesthetics.

-

You're replacing molars or back teeth that endure heavy biting forces.

Ideal Use Cases:

-

Single-unit crowns for molars.

-

3-unit bridges to replace one missing tooth.

-

Posterior restorations where strength matters more than translucency.

-

Patients with metal sensitivity or allergies.

Summary:

| Feature |

Besic Zirconia |

| Strength |

Very High |

| Aesthetics |

Moderate (opaque) |

| Best For |

Back teeth, molars |

| Allergic Reactions |

None (biocompatible) |

| Longevity |

10-15 years or more |

| Units Possible |

1 to 3 (single crown or short bridges) |

| Cost |

Medium to High |

| Maintenance |

Low |

| Edit |

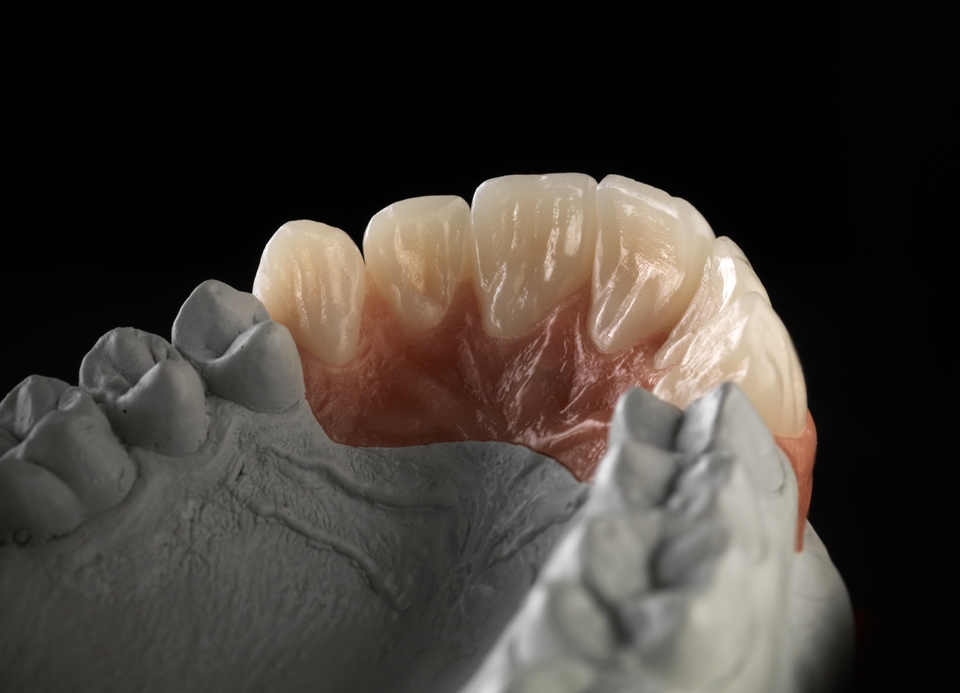

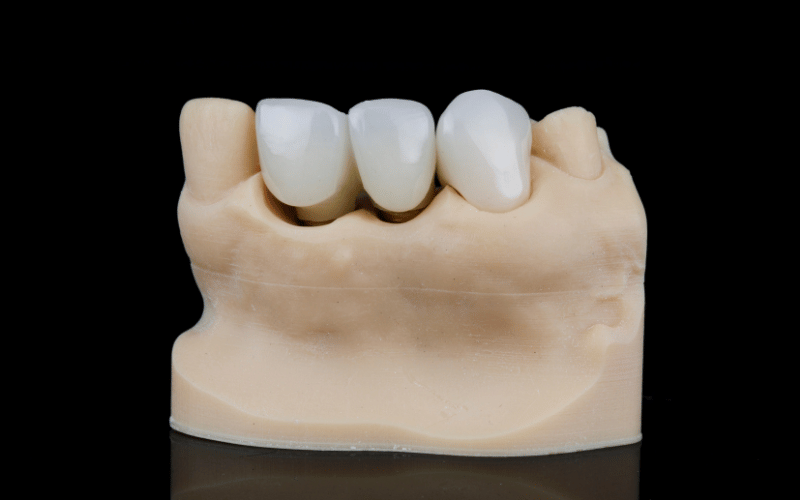

| 4 | Bux Zir |    | 1 to 16 units could be made | What is Bux Zirconia? Bux Zirconia is a high-quality dental material made from zirconium dioxide. It is used to create dental crowns, bridges, and full-mouth restorations. Known for its strength, natural appearance, and safety, it is widely used in modern dental treatments.

Advantages of Bux Zirconia

-

Natural-looking appearance, closely matches real teeth

-

Very strong and durable — ideal for both front and back teeth

-

Long-lasting results (can last 10–15+ years with proper care)

-

Free from metal — suitable for patients with metal allergies

-

Gentle on gums and soft tissues

-

Designed with CAD/CAM technology for high precision

-

Suitable for up to 16-unit bridges

-

Requires less removal of natural tooth structure

-

Resistant to stains and cracks

-

Smooth surface helps reduce plaque buildup

Disadvantages of Bux Zirconia

-

More expensive compared to metal or PFM crowns

-

Requires specialized lab setup and skilled technicians

-

Slightly less translucent than E-max for front teeth

-

If not polished properly, can wear down opposing natural teeth

-

Not ideal for patients with severe teeth grinding (unless specially designed)

How is Bux Zirconia Made?

-

Tooth is prepared by the dentist

-

Impression or digital scan is taken

-

Digital design is created using CAD software

-

Zirconia block is milled using CAM machine

-

Product is sintered at high temperatures

-

Final crown or bridge is polished and customized

-

Dentist fits and cements it in the patient’s mouth

Who Should Choose Bux Zirconia?

-

Patients who want a natural-looking and beautiful smile

-

Those needing a strong and long-lasting dental solution

-

Anyone with metal allergies

-

Patients requiring bridges up to 16 units

-

Individuals who value quality, safety, and durability

ConclusionBux Zirconia offers an excellent combination of strength, beauty, and biocompatibility. Whether for a single crown or a full-mouth bridge, it provides a long-term, reliable solution with high patient satisfaction. Though it is slightly more expensive, its benefits make it a worthwhile investment in dental health and appearance.

| Edit |

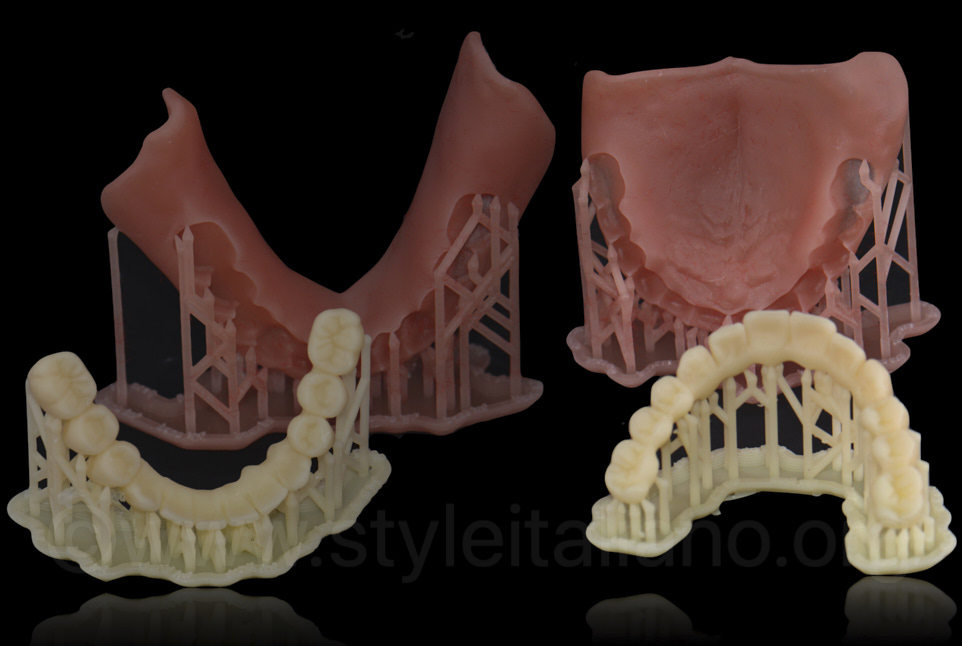

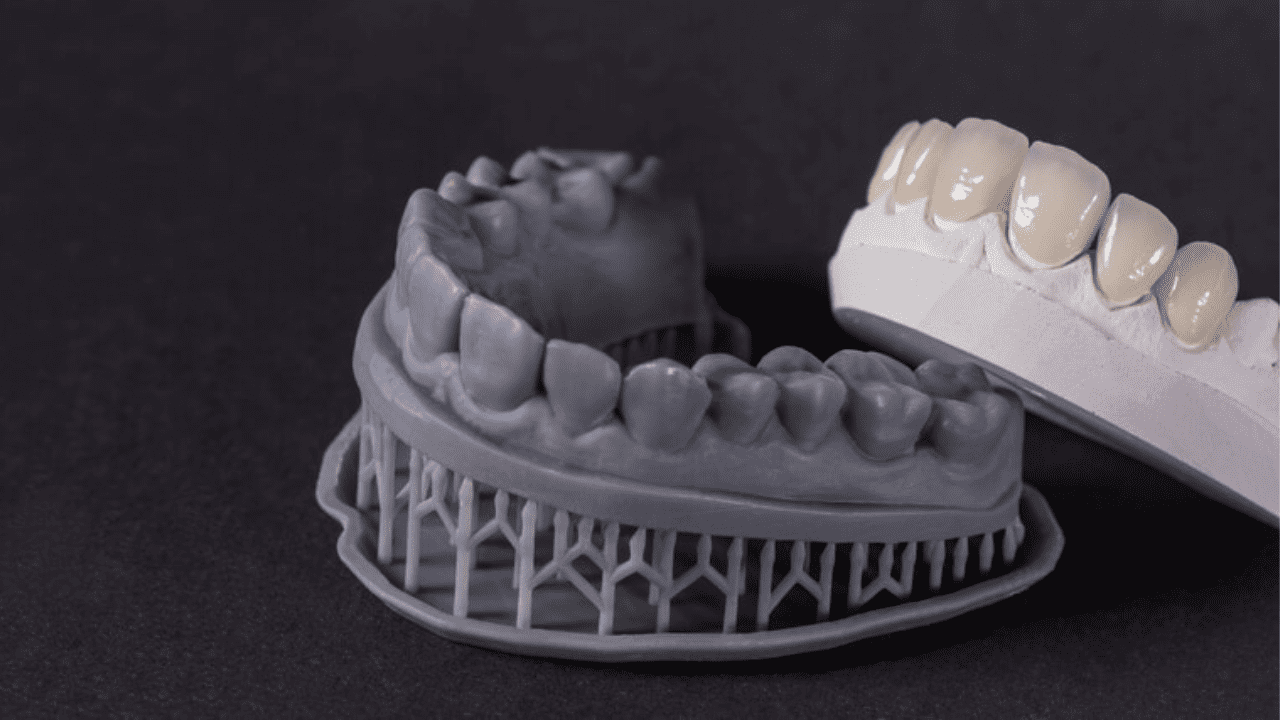

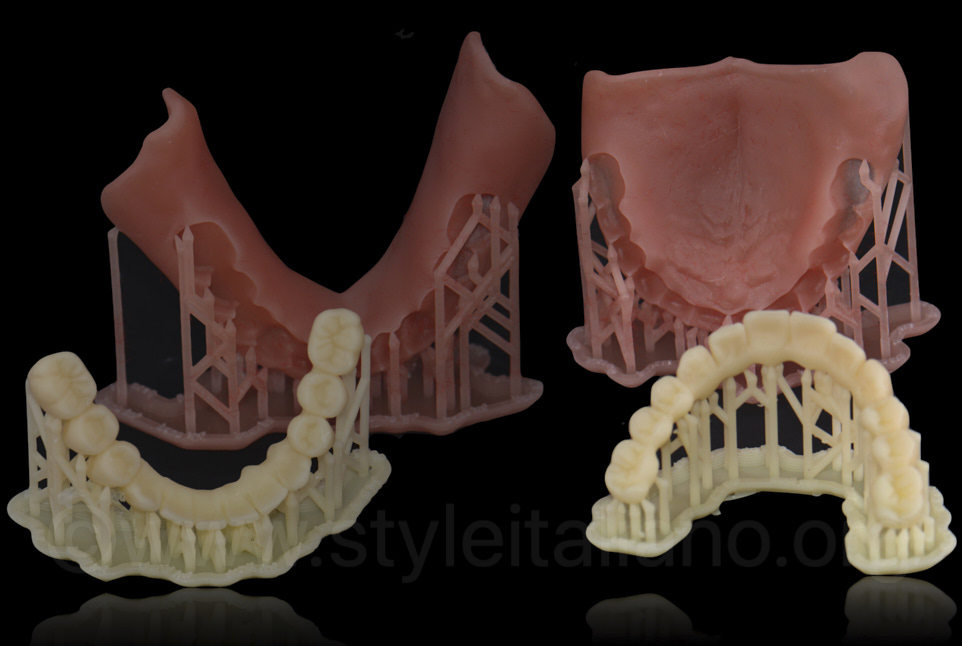

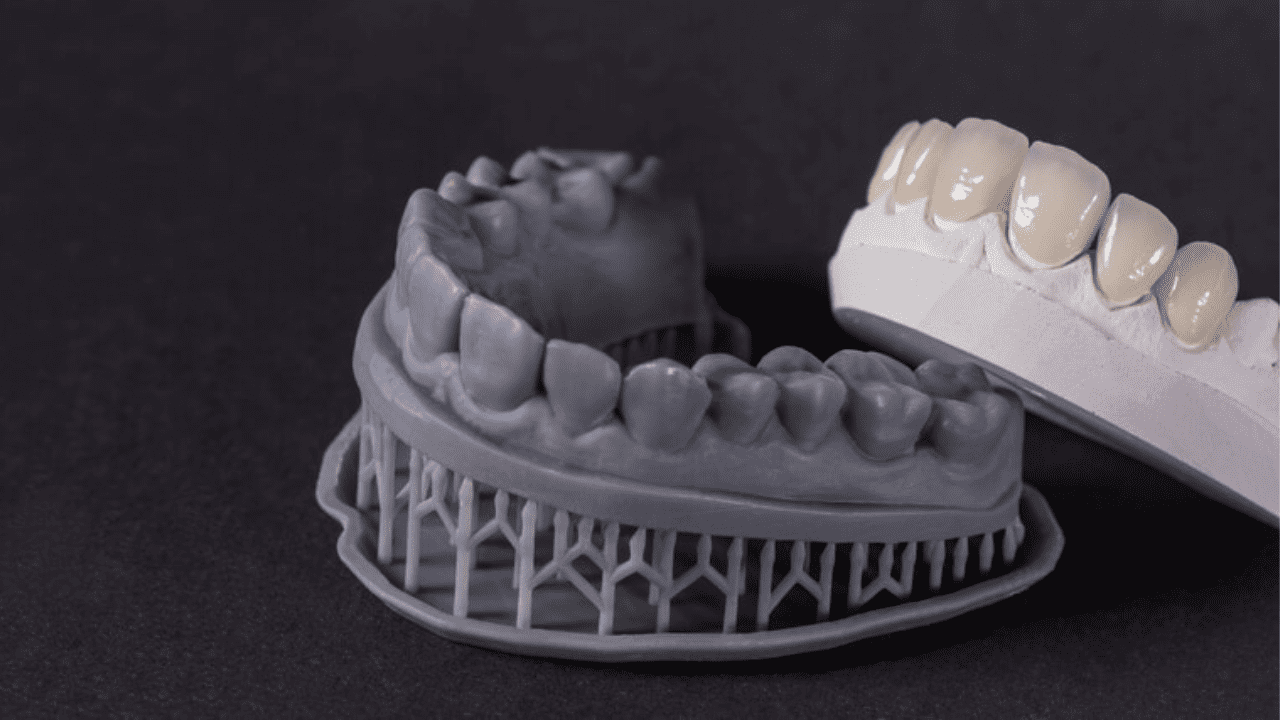

| 5 | CAD CAM (3D Printed) |   | 4 units could be made | 📌 What is CAD CAM (3D Printed)? CAD stands for Computer-Aided Design and

CAM stands for Computer-Aided Manufacturing. When combined with 3D Printing, it means:

We design an object on the computer (CAD), then that design is manufactured (CAM) using 3D printing technology. 👉 Example:

Imagine you want to make a dental crown, an artificial bone, or even a complex machine part.

Instead of manually making it, you first design it on the computer, then the 3D printer prints it layer-by-layer.

🔍 Where is it used?

-

Dental Industry – For crowns, bridges, dentures

-

Medical – Artificial bones, implants

-

Automobile – Custom parts, components

-

Jewelry – Intricate gold/silver designs

-

Aerospace – Precision parts for aircraft

-

Prototyping – For testing before mass production

✅ Advantages of CAD CAM (3D Printed)

| Advantage |

Description |

| 🎯 High Accuracy |

Extremely precise output, especially useful in medical/dental field |

| ⏱️ Fast Production |

Much faster than manual methods |

| ✍️ Customization |

You can design exactly as per client or patient requirement |

| 💰 Cost Saving (Long Term) |

Reduces labor and material waste |

| 🔁 Easy to Edit |

You can easily modify the digital design anytime |

| ♻️ Minimal Waste |

Only required material is used, hence eco-friendly |

| 🔄 Repeatable |

Can create the same item again with exact dimensions |

| 🧪 Pre-check Functionality |

You can simulate and test design before actual print |

❌ Disadvantages of CAD CAM (3D Printed)

| Disadvantage |

Description |

| 💸 High Initial Cost |

3D printers and CAD software are expensive |

| 📚 Skilled Manpower Required |

Need trained designers and operators |

| 🕒 Long Print Time for Large Items |

Some complex designs can take hours |

| 🔍 Material Limitations |

Only specific materials can be used in 3D printing |

| ⚠️ Technical Errors |

Any small design error in CAD can lead to manufacturing defects |

| 🛠️ Maintenance |

Printers require regular maintenance and calibration |

🤔 Why Use CAD CAM with 3D Printing?

-

For better patient care – Like perfect-fit dental crowns

-

For better speed – One crown can be made in a few hours

-

For complex designs – Which are not possible manually

-

For innovation – Test and develop new models quickly

🧾 ConclusionCAD CAM (3D Printed) is a revolutionary technology combining design and production digitally. It is highly useful in industries requiring precision, speed, and customization, such as dental labs, medical sectors, and engineering industries. If you have 4 units that could be made, it means you can create 4 precise, high-quality custom items based on your design — each one identical and perfect for its purpose. | Edit |

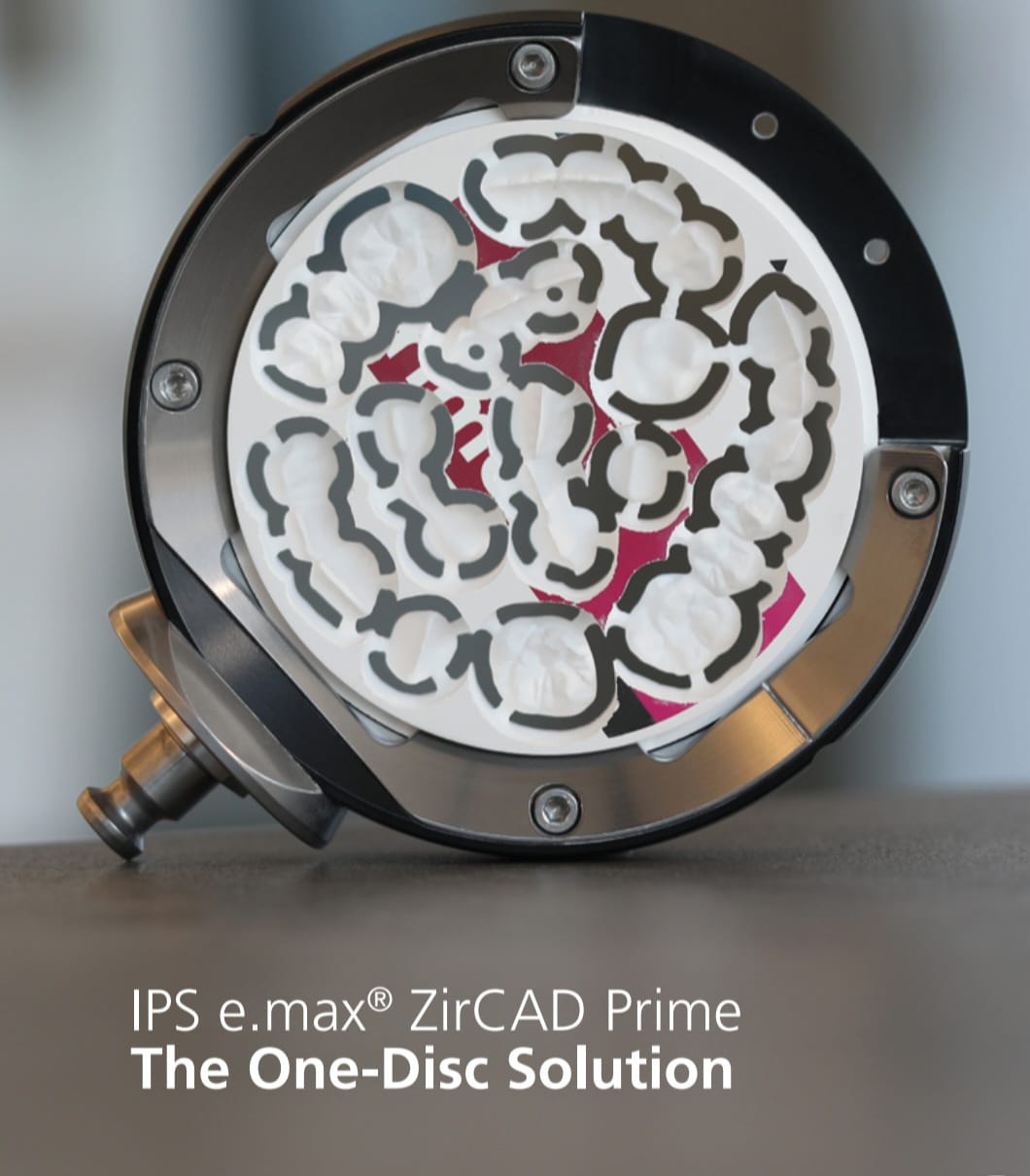

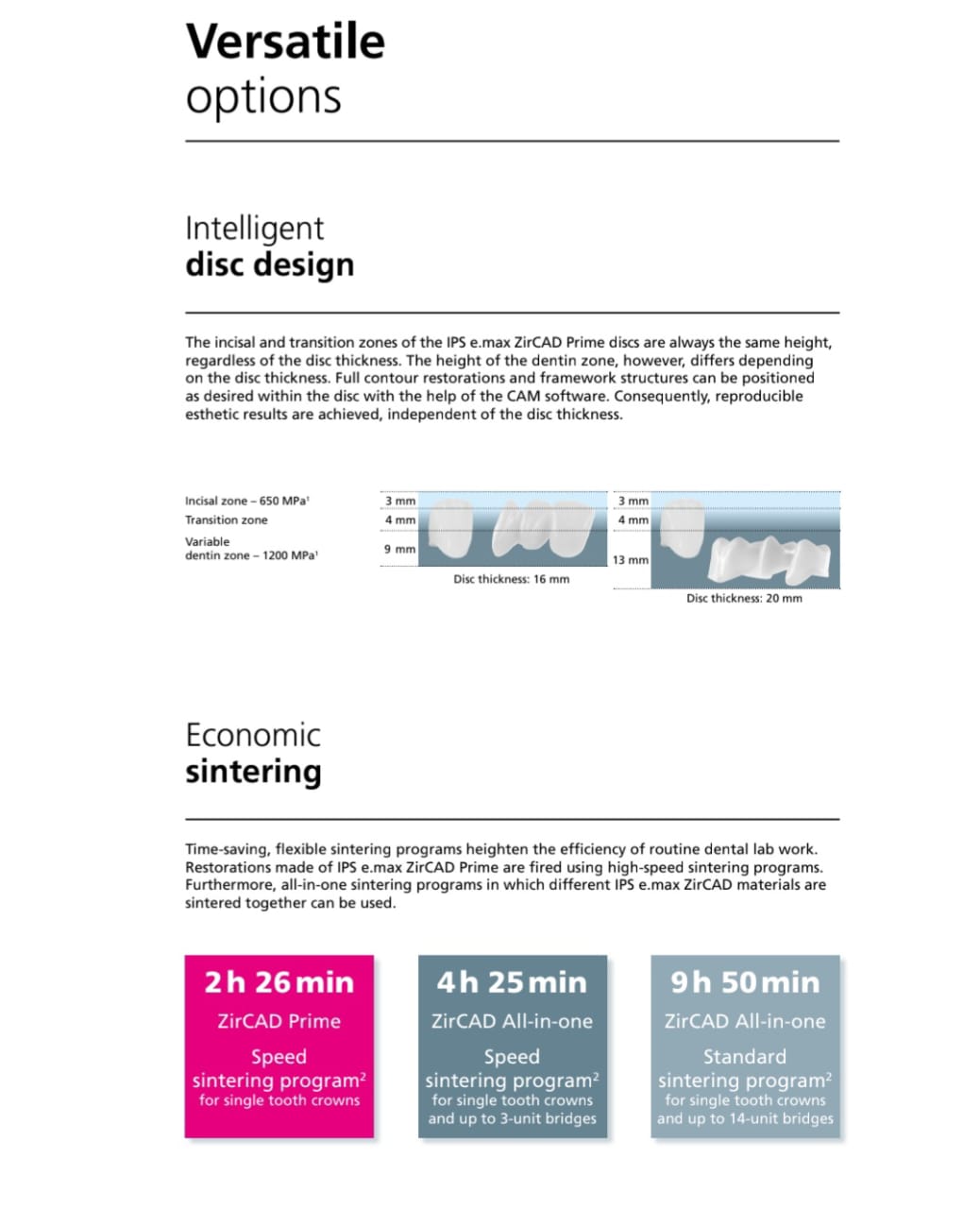

| 6 | Ceramill Material |    | 1 - 3 units could be made | What is Ceramill Material?Ceramill is a branded line of dental materials developed by Amann Girrbach, mainly used in digital dentistry. It is commonly used for making crowns, bridges, frameworks, and prosthetics using CAD/CAM (Computer-Aided Design and Manufacturing) systems. Ceramill materials are typically made of:

-

Zirconia (Zirconium dioxide) – the most common, known for strength.

-

Lithium Disilicate – for better aesthetics.

-

Hybrid ceramics or PMMA – used for temporary crowns or implants.

When you say "1 – 3 units could be made," it means that from one disc or block of Ceramill material, you can create 1 to 3 dental prosthetics (like crowns or bridges) depending on the size.

✅ Advantages of Ceramill Material

-

High Strength and Durability

-

Biocompatibility

-

Excellent Aesthetics

-

CAD/CAM Compatible

-

Minimal Shrinkage

-

Low Thermal Conductivity

-

Long-Lasting Results

-

Less Tooth Reduction

❌ Disadvantages of Ceramill Material

-

High Cost

-

Technique Sensitive

-

Brittleness in Thin Sections

-

Wear on Opposing Teeth

-

Not Suitable for Very Large Bridges

❓ Why Use Ceramill Material?

-

For precision – With CAD/CAM support, it offers exact fittings.

-

For aesthetics – Looks more natural than metal-based restorations.

-

For long-term durability – Especially good for molars and bridges.

-

For comfort and safety – Being metal-free, it suits patients with allergies.

Use Case: When and Where is it Used?

Summary

| Feature |

Ceramill Material |

| Type |

Zirconia / Lithium Disilicate |

| Units per block |

1 – 3 dental restorations |

| Strength |

Very high (up to 1200 MPa) |

| Aesthetics |

High (natural tooth-like look) |

| Lifespan |

10+ years |

| Cost |

Moderate to high |

| Processing method |

CAD/CAM |

| Best for |

Crowns, bridges, aesthetic areas |

| Edit |

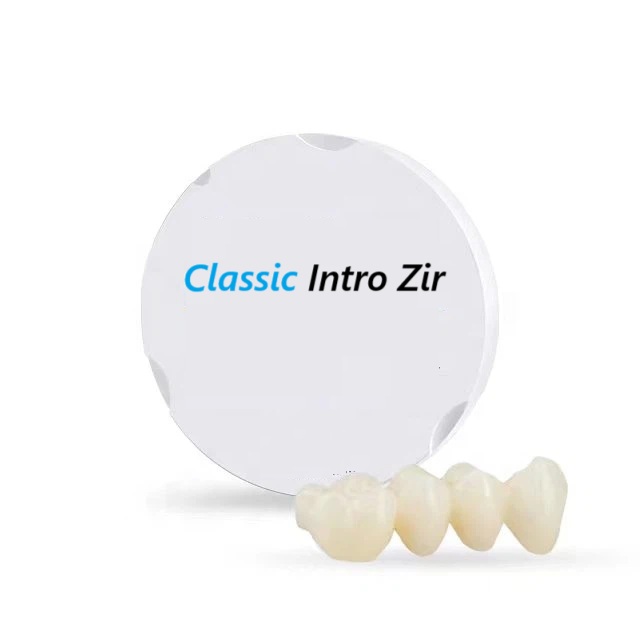

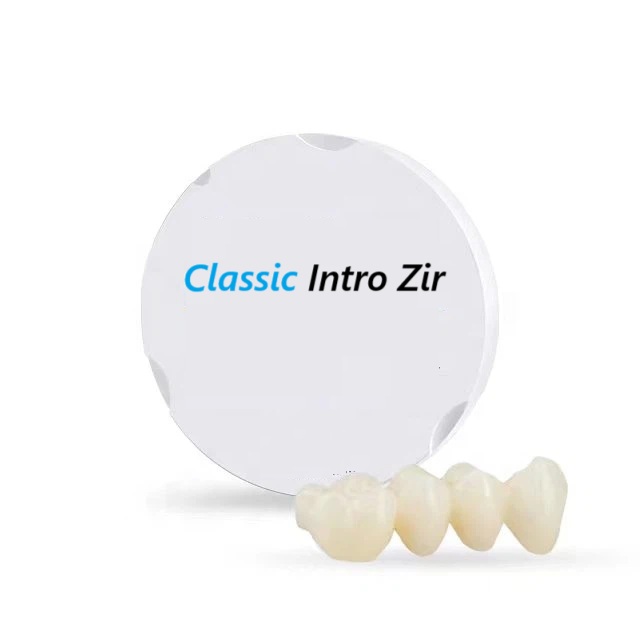

| 7 | Classic-Intro-Zir |    | 1 - 6 units could be made | Kya Features Hain?

-

Made from high-grade Zirconia (ceramic)

-

Looks like natural tooth

-

Suitable for front aur back teeth dono ke liye

-

Customizable in 1 to 6 units – single crown se lekar full bridge tak

✅ Advantages (Fayde):

-

Aesthetic (Sundarta):

-

Natural tooth jaisa dikhta hai.

-

Light pass hone deta hai, isliye real tooth jaisa transparency deta hai.

-

Biocompatibility:

-

Strength & Durability:

-

Metal-free hone ke bawajood, kaafi strong hota hai.

-

Chabane ke dauraan pressure ko handle kar leta hai.

-

Minimal Tooth Reduction:

-

Corrosion Resistant:

-

Digital Workflow Friendly:

❌ Disadvantages (Nuksaan):

-

Costly:

-

Technique Sensitive:

-

Brittle in Thin Sections:

-

Opposing Teeth Damage:

Kab Use Kiya Jata Hai?

-

Root canal treatment ke baad tooth restoration ke liye.

-

Broken ya fractured tooth ke liye.

-

Smile design aur cosmetic dentistry ke liye.

-

Dental bridges (1–6 units tak).

Production Details:

-

Minimum: 1 unit

-

Maximum: 6 unit bridge possible.

-

Custom shade matching available.

-

Digital scanner se precise model banaya jata hai. | Edit |

| 8 | Classic Mono Zir |    | 1 - 3 units could be made | ❓ Kya Hai Classic Mono Zirconia? Classic Mono Zirconia ek dental crown (dant ka top cover) hai jo Zirconium Dioxide naam ke ceramic material se banta hai. "Mono" ka matlab hai monolithic — yani ek hi material se bana hua, bina kisi layering ke. Ye crown pure zirconia block se miling machine ke zariye banaya jata hai. Yeh crown normally 1 se 3 units ke liye recommend kiya jata hai, jaise:

Zirconia Kyu Use Karte Hain?Zirconia ek high-strength, bio-compatible aur tooth-colored material hai jo:

✅ Advantages of Classic Mono Zirconia

| Point |

✅ Detail |

| 1. High Strength |

Bahut hi mazboot hota hai, crack-proof aur breakage resistant. Chewing force ko easily jhel leta hai. |

| 2. Long-Lasting |

10-15 saal ya usse zyada chal sakta hai sahi care ke saath. |

| 3. Biocompatible |

Body ke saath react nahi karta, allergy-free. |

| 4. Less Tooth Reduction |

Preparation mein natural tooth ka kam hissa katna padta hai. |

| 5. Metal-Free |

Pura ceramic hai, isliye gum discoloration ya metal allergy ka risk nahi. |

| 6. Precise Fit |

CAD/CAM se bana hota hai, isliye perfect fitting deta hai. |

| 7. Economical |

Compared to layered zirconia or E-max, yeh thoda sasta padta hai. |

❌ Disadvantages of Classic Mono Zirconia

| ⚠️ Point |

❌ Detail |

| 1. Less Translucent |

Natural tooth ke mukable thoda opaque lagta hai, front teeth (aesthetic zone) mein artificial look de sakta hai. |

| 2. Staining over time |

Agar polish theek se na ho to surface stain le sakta hai (tea, coffee, etc.). |

| 3. Tough to Adjust |

Bahut hard hone ki wajah se chairside adjustments tough hote hain. |

| 4. Wear on Opposing Teeth |

Agar polish rough ho to saamne wale dant ko ghis sakta hai. |

| 5. Limited Shade Matching |

Layered crowns ke mukable iska shade match thoda limited hota hai. |

Suitable Cases:

-

Posterior (back side) teeth ke liye ideal hai jahan aesthetics se zyada strength important hoti hai.

-

Short bridges jahan 1–3 units ho.

-

Patients jinhe metal allergy ho.

-

Jaw clenching or night grinding waale patients.

❓ Classic Mono Zirconia Kyun Choose Karein?Agar aap:

-

Durable solution chahte hain

-

Zyada strong aur long-term option dhoondh rahe hain

-

Metal-free restoration chahte hain

-

Posterior teeth ke liye restoration karwana chahte hain

To Classic Mono Zirconia is the best value-for-money choice. | Edit |

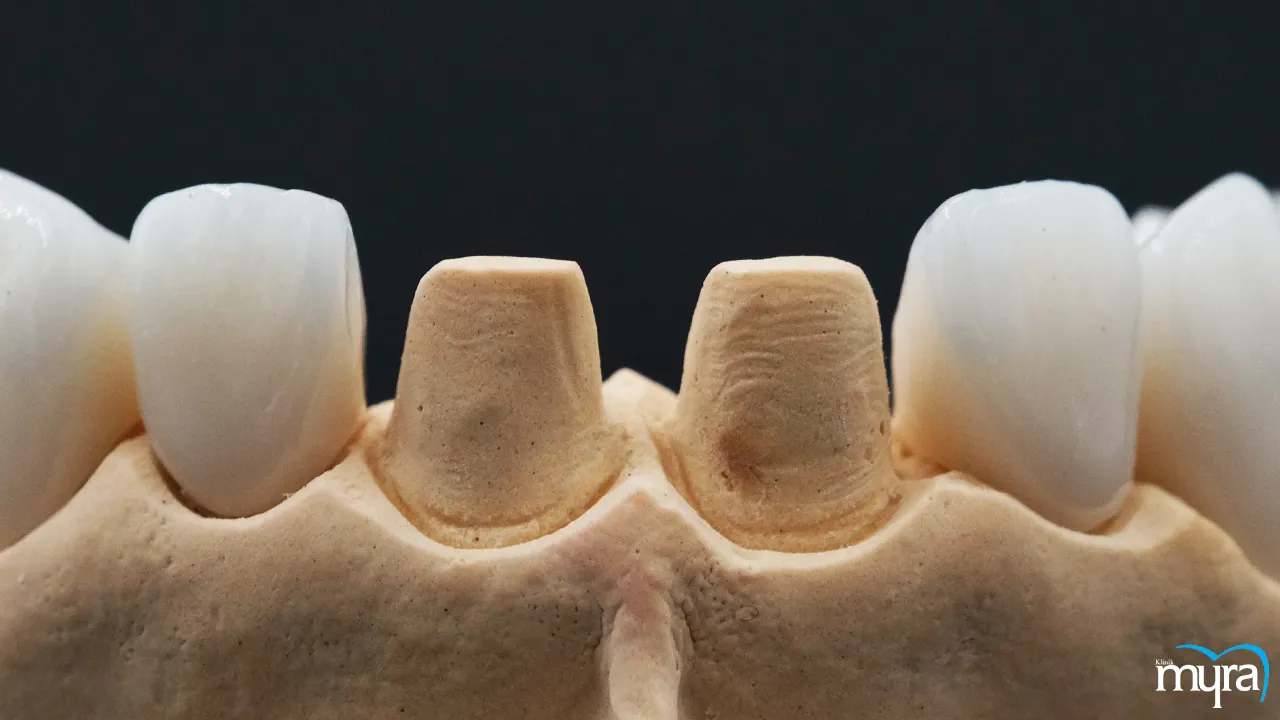

| 9 | Crown CAD CAM |     | 1 to 16 units could be made | What is Crown CAD CAM (1 to 16 units)? Crown CAD CAM refers to dental crowns that are designed using CAD (Computer-Aided Design) and manufactured using CAM (Computer-Aided Manufacturing) technology. It is a modern digital process to create high-precision dental crowns for restoring damaged teeth.

⚙️ How it Works? (Process of Crown CAD CAM)

-

Digital Scanning – The dentist takes a digital impression of the patient's teeth using an intraoral scanner.

-

Design (CAD) – The scanned data is used to design the crown virtually using special software.

-

Manufacturing (CAM) – The design is sent to a milling machine or 3D printer to create the crown from ceramic, zirconia, or other dental materials.

-

Finishing & Fitting – The crown is polished, glazed, and placed in the patient’s mouth after final adjustment.

✅ Advantages of Crown CAD CAM

| Advantage |

Details |

| High Precision |

Digital design ensures perfect fit and accuracy. |

| Speed |

Same-day crown delivery possible in many cases. |

| Durability |

Strong materials like zirconia ensure long life. |

| Aesthetics |

Natural-looking crowns that match tooth color. |

| Comfort |

No messy impressions; uses digital scan. |

| Customization |

Multiple crowns (1 to 16) can be tailored exactly for each tooth. |

| Consistency |

Reduced human error compared to traditional methods. |

| Better Bite |

Proper alignment helps in accurate occlusion and chewing. |

❌ Disadvantages of Crown CAD CAM

| Disadvantage |

Details |

| Cost |

More expensive than traditional methods due to digital equipment. |

| Technology Dependency |

Requires trained staff and machines. |

| Material Limitations |

Some aesthetic materials still look better when handmade. |

| Initial Investment |

Clinics need to invest in expensive scanners and mills. |

| Not Suitable for All Cases |

Complex cases may still require manual touch-ups. |

Why Choose CAD CAM Crowns (1 to 16 units)?

-

If you're looking for accuracy, speed, and aesthetics in dental restoration.

-

Ideal for full-mouth rehabilitation or multiple teeth restoration.

-

Offers consistency when creating multiple units – ensures harmony in size, shape, and bite.

-

Digital records make future replacements or adjustments easier.

-

It's a modern, patient-friendly solution with faster turnarounds.

Applications of Crown CAD CAM

| Edit |

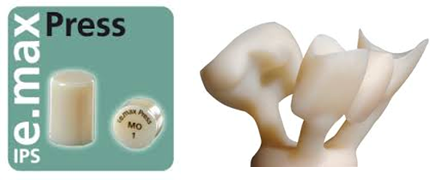

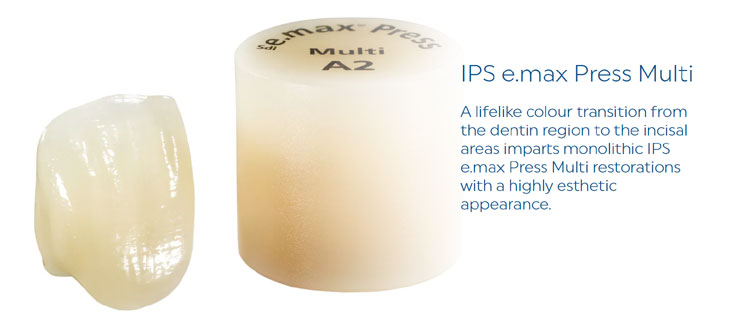

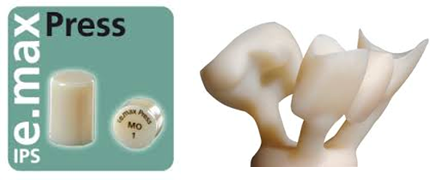

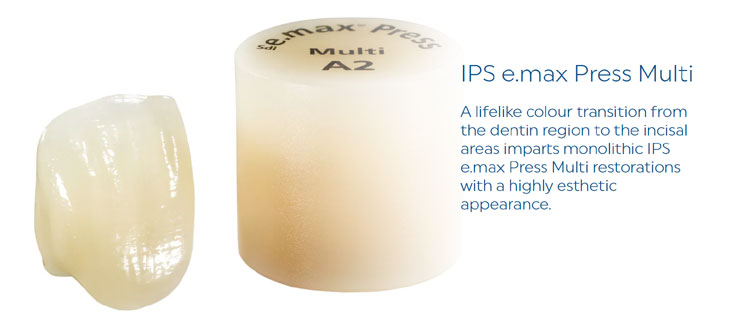

| 11 | e.max Press |    | Only 1 units could be made | What is e.max Press? e.max Press is a premium-quality lithium disilicate glass-ceramic material used in dental restorations. It's most commonly used to create crowns, veneers, inlays, onlays, and implant-supported restorations. It’s made using pressable ceramic technology, which allows highly accurate and aesthetic restorations with great strength and beauty.

⚙️ How it Works

-

A wax pattern of the restoration is created.

-

The pattern is invested and burned out.

-

The ceramic is then pressed (like molten metal) into the mold using special e.max ingots.

-

It is then finished, polished, or layered with porcelain for extra beauty.

✅ Advantages of e.max Press

-

Highly Aesthetic

-

High Strength

-

Minimal Tooth Reduction

-

Biocompatible

-

Versatile

-

Can be used for crowns, veneers, inlays, onlays, and bridges (up to 3 units in some cases).

-

No Metal

-

Stain Resistant

❌ Disadvantages of e.max Press

-

Costly

-

Technique Sensitive

-

Limited for Long Bridges

-

Only One Unit Made (Your Case)

-

Possibly due to:

-

Limited stock of e.max ingots.

-

Custom shade requirement.

-

Single-use precision mold.

-

Cost constraints.

-

May Fracture if Misused

Why Only One Unit Can Be Made?This could be because:

-

The process is customized for a specific patient.

-

Each e.max Press crown is handcrafted and pressed individually.

-

The wax mold and investment are designed for a single-use cycle.

-

Once pressed, the mold breaks — so mass production is not possible.

-

Inventory or cost limitations — e.max materials are premium and costly.

Summary / Samjhein Kaise:

| Point |

Description |

| Kya hai? |

Dental crown material — strong & natural-looking ceramic |

| Kaise banta hai? |

Wax mold + high-pressure press technique |

| Kyu chahiye? |

Beauty, durability, and safety — best for visible teeth |

| Advantage kya hai? |

Looks real, strong, no metal, safe for body |

| Disadvantage kya hai? |

Mehenga hai, expert chahiye, long bridges ke liye nahi |

| Sirf 1 unit kyun? |

Ek hi mold se ban sakta hai, stock ya requirement specific ho sakti hai |

Ideal For:

-

Front teeth crowns and veneers

-

Patients who want a perfect smile

-

Allergy-prone individuals (metal-free option) | Edit |

| 12 | Glass PFM |    | 1 - 16 units could be made | What is Glass PFM? PFM stands for Porcelain Fused to Metal.

Glass PFM refers to dental crowns or bridges where a metal base is covered with glass-like porcelain (ceramic) to look like a real tooth. It combines strength (metal) with natural appearance (porcelain/glass). This product is mainly used in dental prosthetics (like artificial teeth), especially for patients needing tooth replacement.

⚙️ How is Glass PFM Made?

-

Metal Framework Creation:

-

Porcelain/Glass Layering:

-

Shaping and Coloring:

-

Final Polishing:

Why Use Glass PFM?

-

To replace damaged or missing teeth

-

To improve the appearance of teeth

-

To restore chewing function

-

To protect a weakened tooth after root canal

✅ Advantages of Glass PFM:

| Sr |

Advantage |

Description |

| 1️⃣ |

Strength |

The metal base gives it high strength, suitable for both front and back teeth. |

| 2️⃣ |

Natural Look |

The outer glass layer looks like a real tooth. |

| 3️⃣ |

Durability |

Can last 10-15 years with proper care. |

| 4️⃣ |

Affordable |

Cheaper than all-ceramic or zirconia crowns. |

| 5️⃣ |

Well-tested |

Used successfully for decades in dentistry. |

| 6️⃣ |

Less Tooth Cutting |

Requires less reduction than full-metal or zirconia in some cases. |

❌ Disadvantages of Glass PFM:

| Sr |

Disadvantage |

Explanation |

| 1️⃣ |

Porcelain Chipping |

Outer layer may chip under heavy bite pressure. |

| 2️⃣ |

Metal Visibility |

A dark line near the gums may appear over time (metal margin). |

| 3️⃣ |

Not Fully Aesthetic |

Not as natural-looking as all-ceramic crowns in front teeth. |

| 4️⃣ |

Allergic Reactions |

Some patients may have allergies to metals used. |

| 5️⃣ |

Heavier |

Slightly heavier than pure ceramic or zirconia. |

Where is Glass PFM Used?

Who Should Choose Glass PFM?

-

Patients needing a strong and economical crown

-

Patients looking for long-term dental solution

-

Ideal for back molars where strength is more important than aesthetics

⚠️ Who Should Avoid It?

-

People with metal allergies

-

Patients requiring high-end aesthetic restoration for front teeth

-

If the gum line is highly visible and you want a fully natural appearance

Summary Table:

| Feature |

Details |

| Product |

Glass PFM |

| Quantity |

1 - 16 Units |

| Use |

Dental Crown/Bridge |

| Core Material |

Metal (Ni-Cr, Co-Cr) |

| Outer Layer |

Glass-ceramic/porcelain |

| Lifespan |

10-15 years |

| Price |

Affordable compared to Zirconia |

| Best For |

Back teeth, high-strength need |

| Edit |

| 13 | Heat Cure Acrylic |   | 1 - 16 units could be made | | Edit |

| 14 | Inlay |   | 1 units could be made | | Edit |

| 15 | Light Cure crown |    | 1 units could be made | | Edit |

| 16 | PMMA (CADCAM-Milled) |   | 1 units could be made | | Edit |

| 17 | Self Cure Acrylic |   | 1 units could be made | | Edit |

| 18 | Veneer |   | 1 units could be made | | Edit |

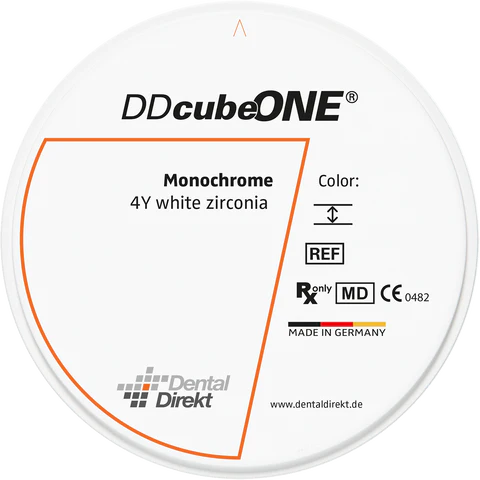

| 19 | DD Bio Y20 |    | 1 to 16 units could be made | | Edit |

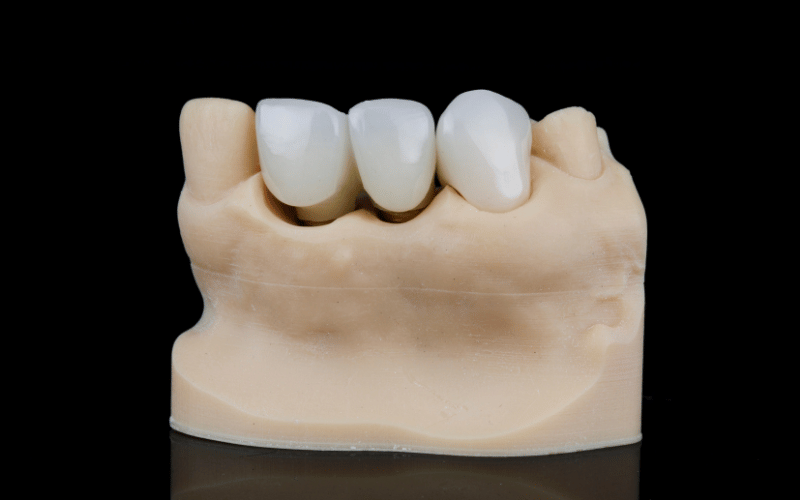

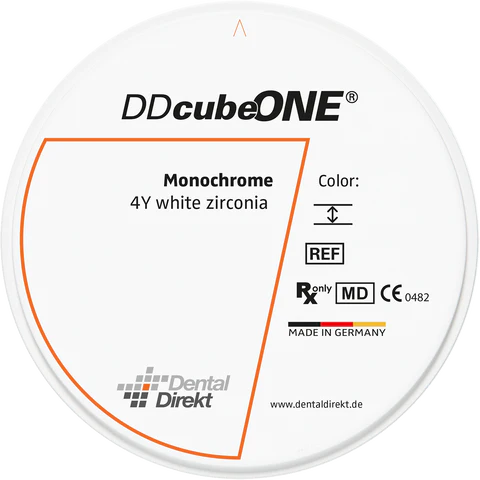

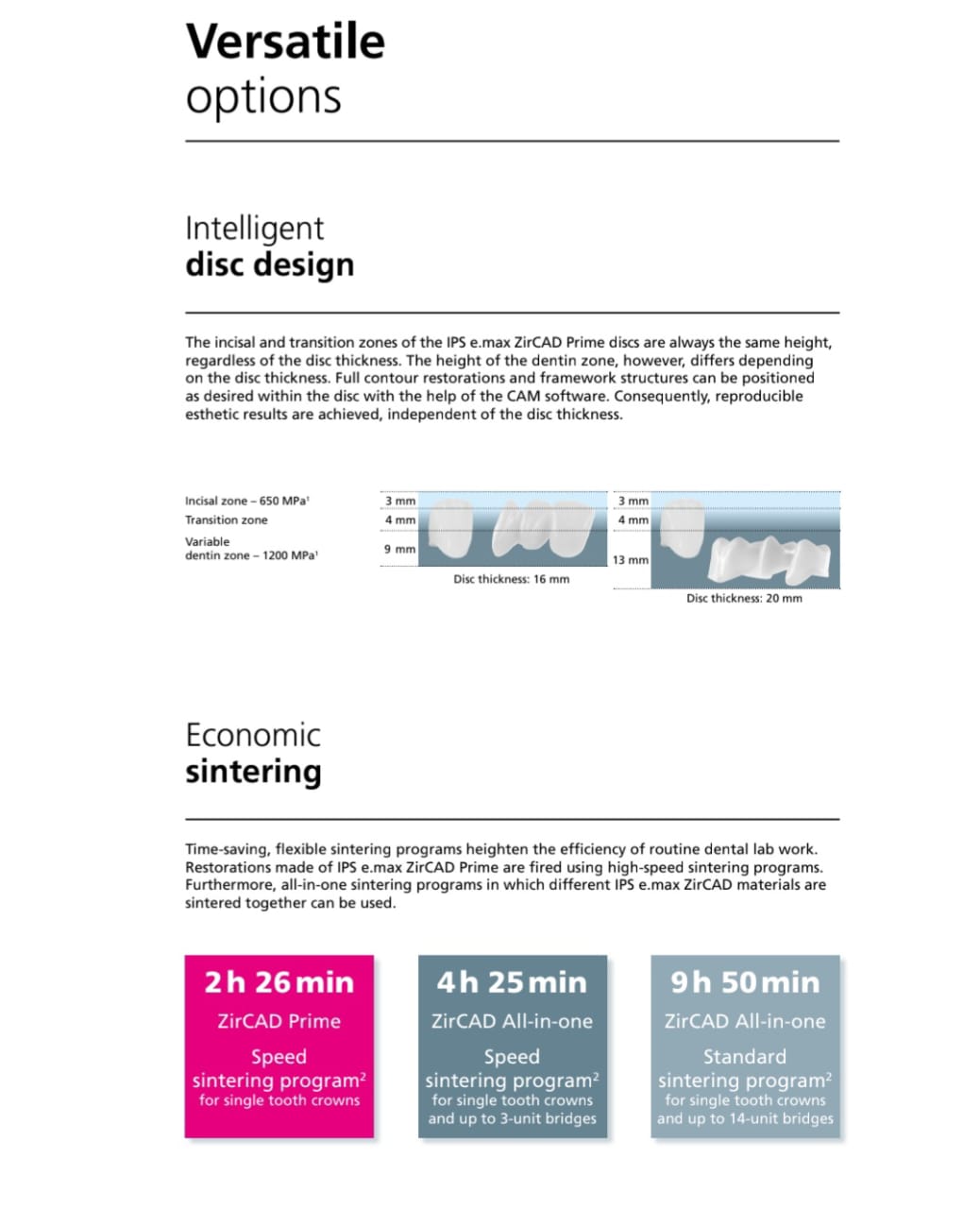

| 20 | DD Cube Y15 |   | 1 - 4 units could be made | Perfect Balance of High Resistence and High Translucency

Excellent Strength and Highest Fracture toughnesss(10 Mpam)

Unique Results Due to Multilayer Concept

All Indications(anterior & posterior) with One Zirconia | Edit |

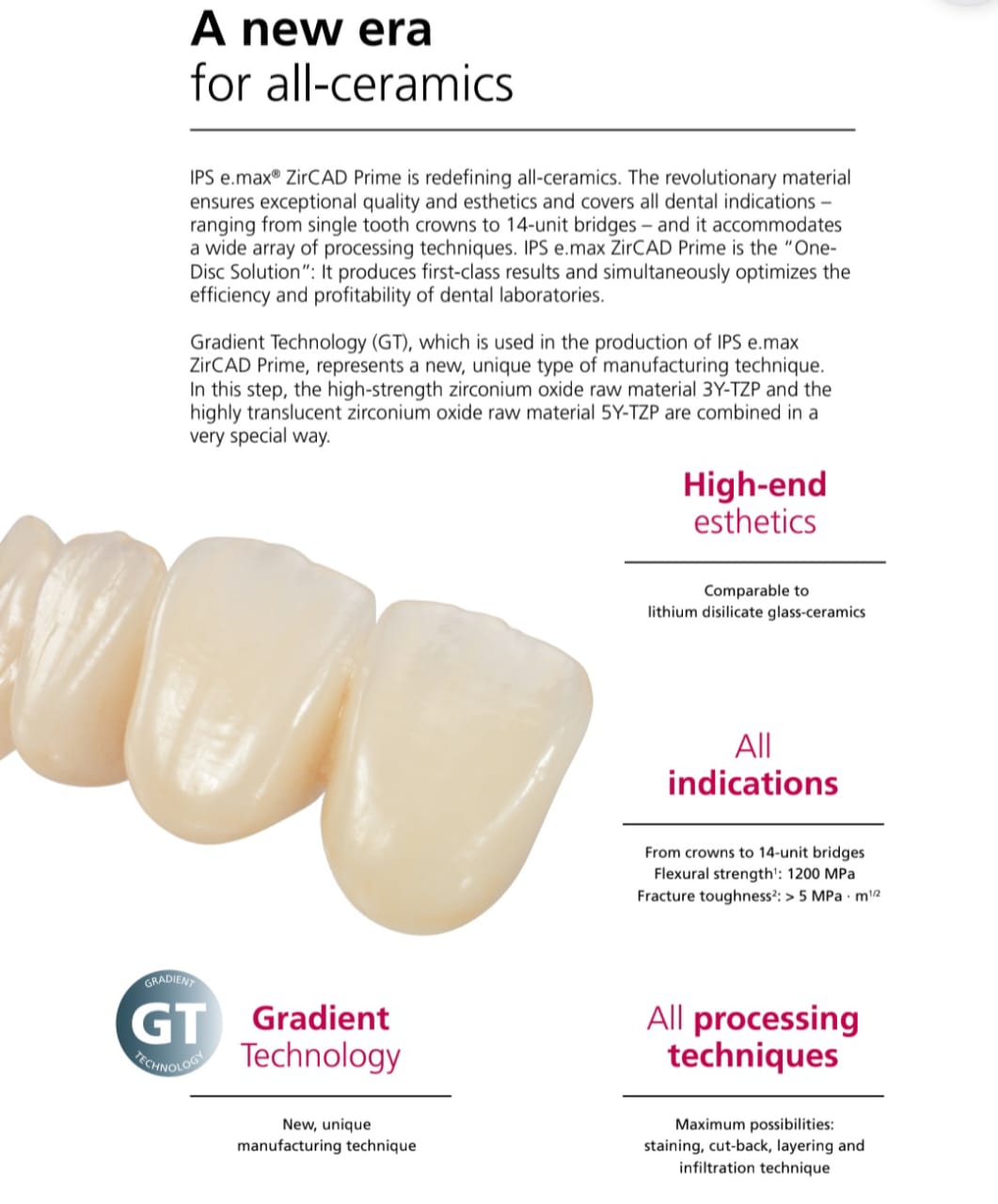

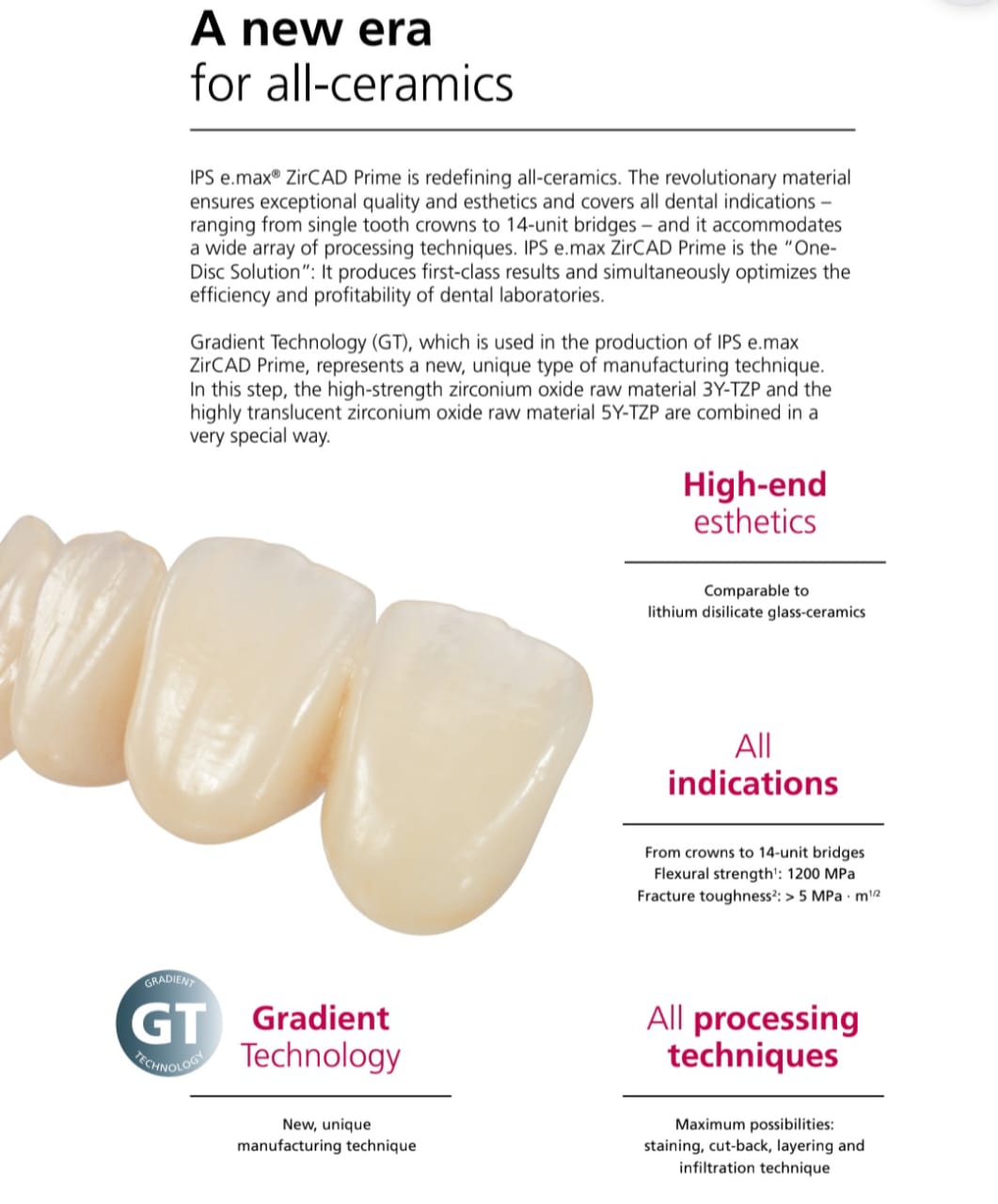

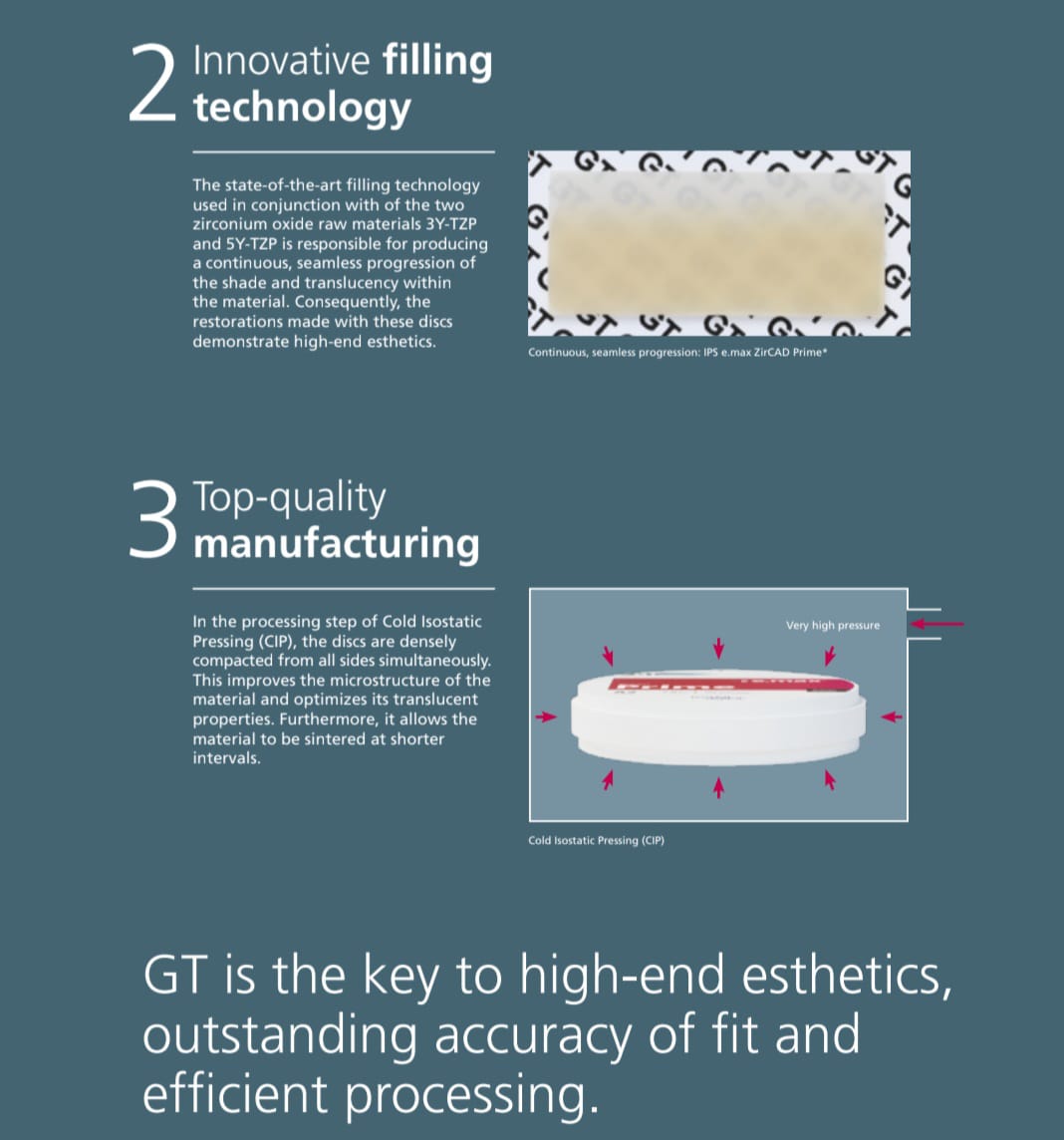

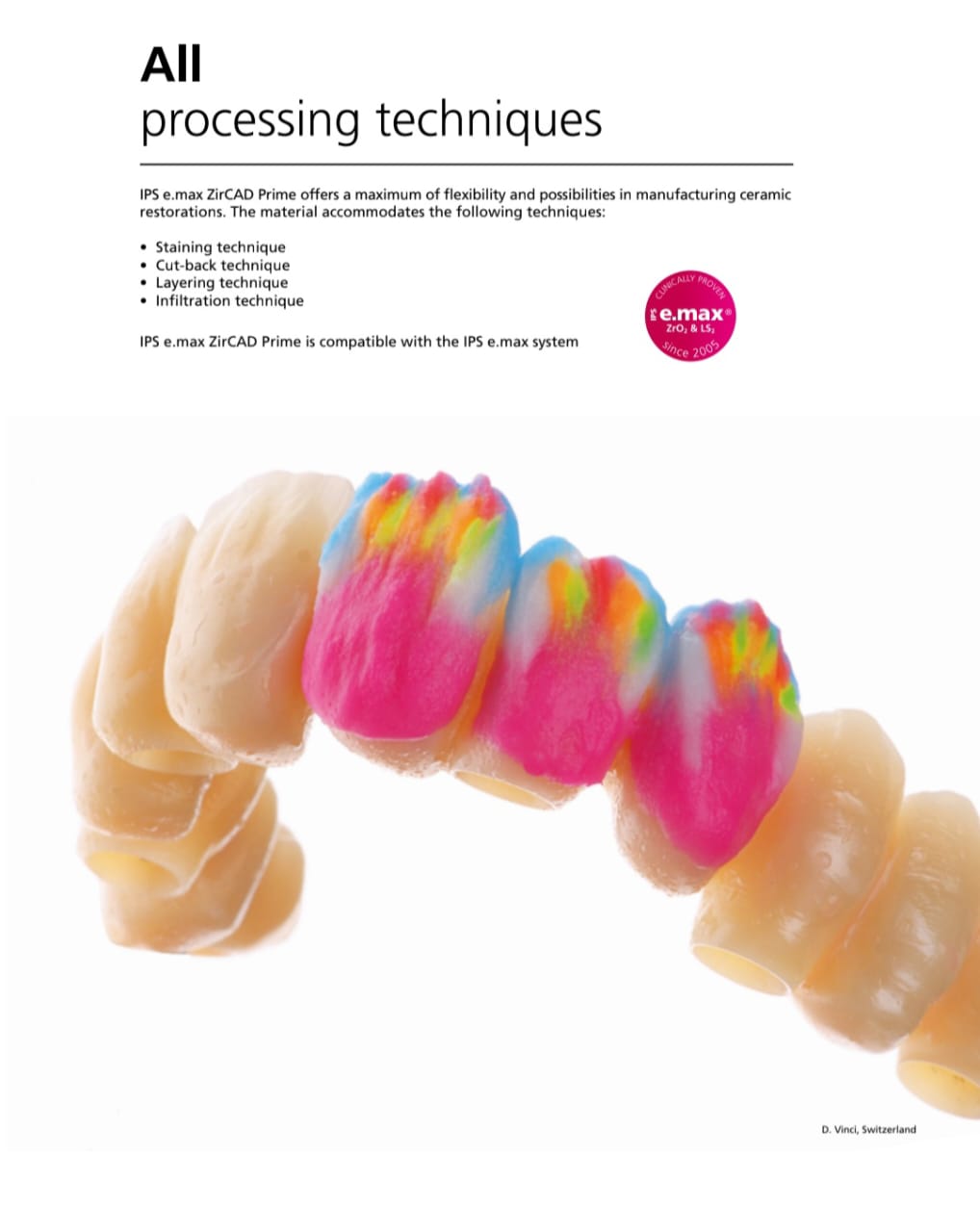

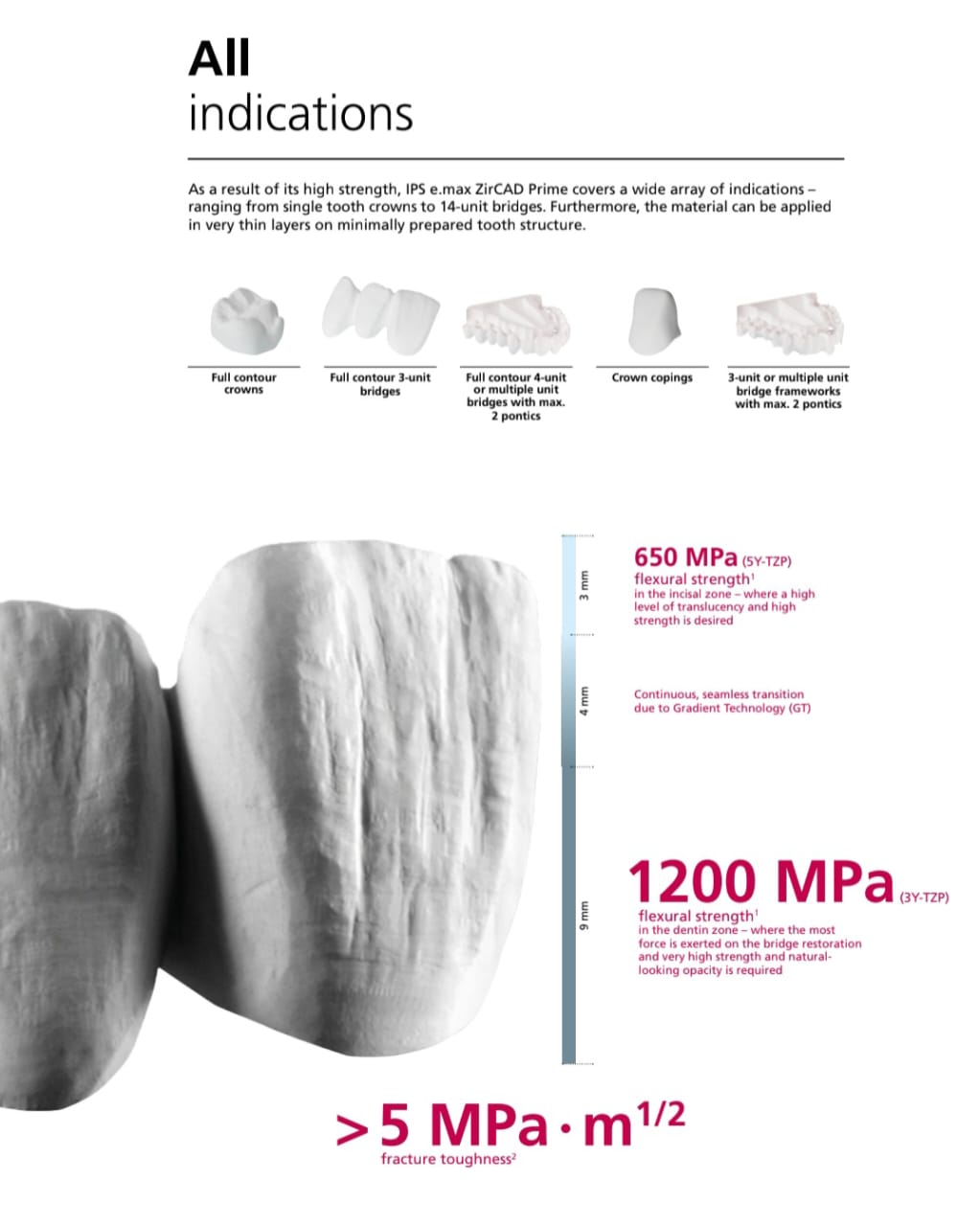

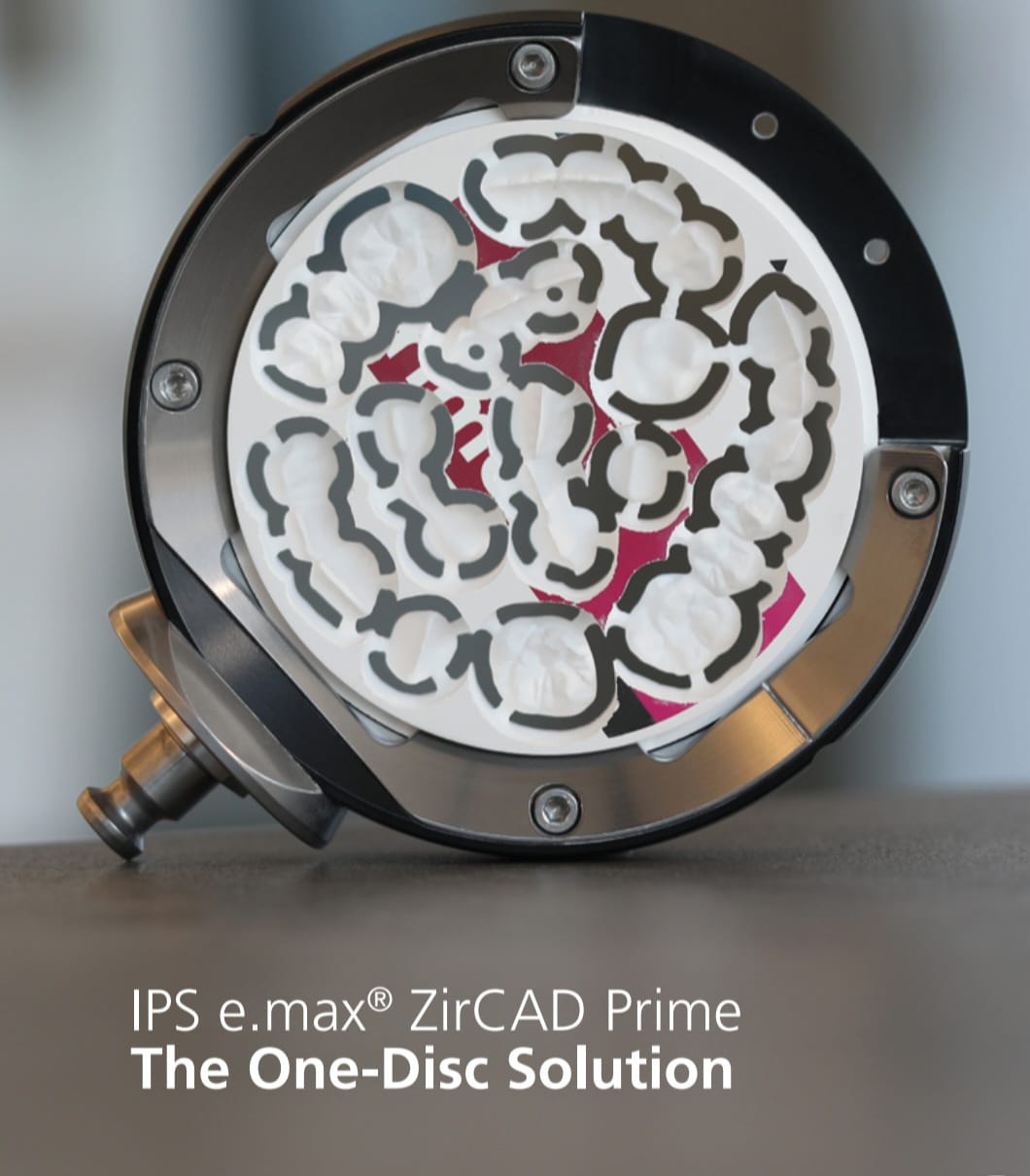

| 22 | e.max CAD Prime |         | 1 to 16 units could be made | | Edit |

| 23 | DMLS crowns |       | 1 - 16 units could be made | What are DMLS crown?

Dental crowns manufactured with the DMLS 3D printing method are known as DMLS crowns. The DMLS procedure uses a laser to layer-by-layer sinter metal powder particles to produce a precise and incredibly accurate 3D model of the desired crown. The standard procedure to manufacture DMLS dental crowns is as follows

Advantages:

* Precision: DMLS allows for highly

accurate and customized crowns.

* Strength and Durability: The metal

materials used in DMLS crowns are

known for their strength and ability to

withstand the stresses of chewing and

biting

* Durability: DMLS crowns are incredibly

durable and can last for many years with

proper care. | Edit |